Fired Clay, Earth Cement Sand & Water

FIRED CLAY, EARTH CEMENT SAND & WATER

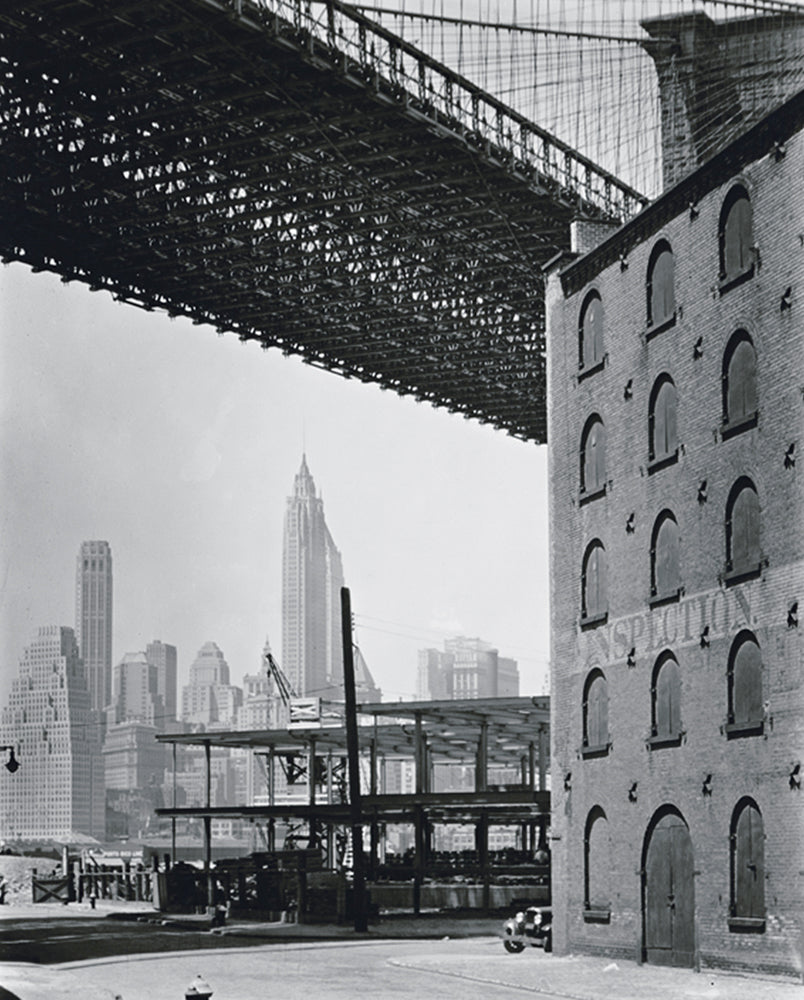

In the spectrum of building materials, there is nothing as human as brick. Formed by hand, stamped by region, workable by a single man — it is one of the first building materials on the historical record, going back some 8,000 years to the dawn of civilization in the Fertile Crescent.

Brickmaking first spread across the globe from the Middle East. The Chinese, as with most things, were early adapters of the technology. Fragments found at Xi’an in Shaanxi date back as many as 3,800 years. They used the material most famously — both sunbaked and kiln-fired varieties—in their Great Wall (210 BC).

The Romans were no slouches themselves. It is said that the legions of the empire operated mobile kilns, imposing their brick on every land they conquered and produced one of the most distinctive of brick dimensions. Long and narrow in profile, it was brought back to popularity in the 20th century by Frank Lloyd Wright, who employed them to stunning effect in his Prairie School homes.

But perhaps the most human thing about brick is its size. While proportions vary from country to country, they are generally formed so that they can be held in one hand, while the other uses a trowel. Twice as long as they are wide, the shape also allows them to be laid in alternating courses, a method that increases structural integrity. Bricks from northern regions are typically thicker, and more insulating than those from southern climes. And, before our advanced means of transportation, all bricks were fabricated near the building site, which meant that color, texture, size — the whole feel of the material — varied from region to region. Methods and form depended on the type of clay available, as well as the type of kiln people built.

“But perhaps the most human thing about brick is its size. While proportions vary from country to country, they are generally formed so that they can be held in one hand, while the other uses a trowel.”

Here in the 21st century bricks are still formed from clay and fired in kilns, only the process has become increasingly industrialized and automated; and consequently less human. In a modern facility, clay is extruded through a form much like a Play-Doh Fun Factory, cut with a wire screen, and rolled through a kiln on a conveyor belt. The process produces very precise results. Color, texture, and shape can be calibrated by simply switching out a few parts and twisting a few knobs. And yet, for all that efficiency, modern bricks lack the romance, if you will, of old handmade varieties.

Once upon a time bricks were also stamped with the name of the brickyard that made them, a custom going back again to the Romans, whose legions always marked their work. The Chinese also mandated that brickmakers — like weapon makers — stamp their products so that if they proved to be defective the liable party could easily be identified. In short, the brick was always cultural; specific to the time and the place and the people who made it.